Window Wall

Products and Applications

Window wall is defined in NAFS as, “A non-load-bearing fenestration system provided in combination assemblies and composite units, including transparent vision panels and/or opaque glass or metal panels, which span from the top of a floor slab to the underside of the next higher floor slab. NOTE: Window walls are available with separate or integral slab edge covers and can be fabricated from windows or curtain wall or storefront systems. Primary provision for anchorage occurs at head and sill conditions. Receptor systems can be designed as a part of drainage and movement accommodation provisions.”

Window wall is defined in NAFS as, “A non-load-bearing fenestration system provided in combination assemblies and composite units, including transparent vision panels and/or opaque glass or metal panels, which span from the top of a floor slab to the underside of the next higher floor slab. NOTE: Window walls are available with separate or integral slab edge covers and can be fabricated from windows or curtain wall or storefront systems. Primary provision for anchorage occurs at head and sill conditions. Receptor systems can be designed as a part of drainage and movement accommodation provisions.”

Window wall “rests” on the floor below, and expands in the same direction as interior finishes, for easy interfaces at door openings and balcony slabs. Shear walls and changes in sill height are straightforward. Window wall can be installed in any sequence.

Window wall can be designed to look as much - or as little - like curtainwall as desired. Performance criteria are similar. Window wall made from window systems - like Wausau’s INvent™ product family - looks more “residential,” with expressed interior glazing beads, and framing sightlines interrupted by offsets. Optional beveled or profiled glazing rebates are available, while vents are integrated into framing. Structural silicone glazing is generally unavailable.

Window wall made from unitized curtainwall - like Wausau’s INvision™ product family - looks more “commercial,” with rectilinear mullion proles interior and exterior, and glazed-in insert vents. “Chicken head” starters are used at slab conditions. SSG is optional.

To learn more:

Download Wausau's "Window Wall Products and Applications" brochure [PDF]

Download Wausau's "Invent™ Series" brochure [PDF]

Contact Wausau's high rise market manager at highrise@wausauwindow.com

View Wausau's window solutions for Apartments, Condos, and Hotels

INvent™

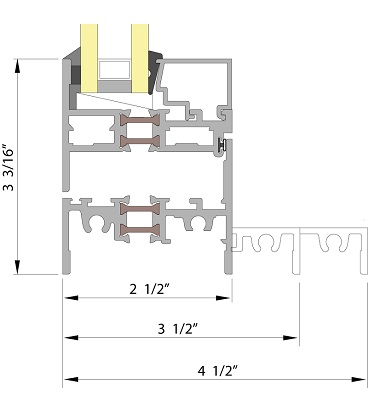

2250i, 3250i and 4250i INventTM Series

- 2 1/2”, 3 1/2” and 4 1/2” frame depth with polyamide thermal barrier

- AAMA AW-100 Performance Class

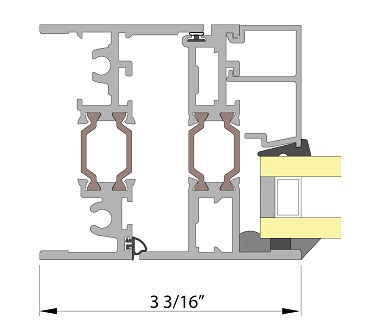

4250i-OS Offset INventTM Series

- 4 1/2” frame depth with polyamide thermal barrier

- AAMA AW-100 Performance Class

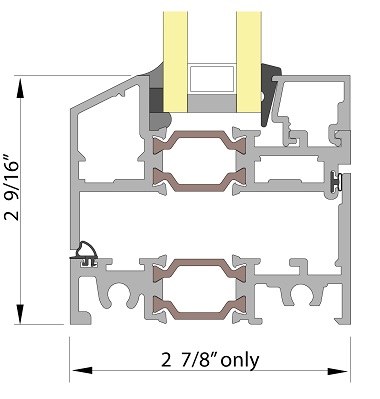

INvent™ XLT

2250i, 3250i and 4250i-XLT INventTM Series

- 2 7/8”, 3 7/8” and 4 7/8” frame depth with extra-wide polyamide thermal barrier

- AAMA AW-100 Performance Class

INventTM 3250i- and 4250i-HP-XLT Series HURRICANE

- 3-7/8" (3250i) and 4-7/8" (4250i) frame depth

- 24mm XLT polyamide thermal barrier

- AAMA AW-100 Architectural Performance Class

INvent.PLUS™

- 3-11/16”, 4-11/16”, 5-11/16” frame depths available

- AAMA AW-100 Performance Class

- Best-in-class R6 fixed and R5 operable thermal performance.

INvent™ Retro

- 2 7/8”, 3 7/8” and 4 7/8” frame depth with extra-wide polyamide thermal barrier

- AAMA AW-100 Performance Class

- Beveled, cove, ogee or square exterior face to replicate putty-glazed window profiles

- Equal sightline option at vents and fixed lites (2250i-XLT)